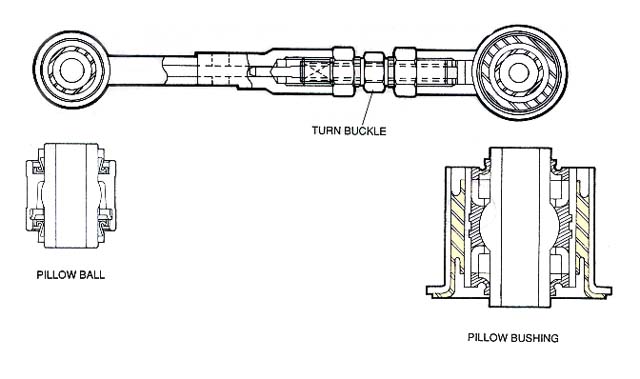

An important aspect of this E.E. kit is that the pivot point remains in the same point as stock. I did a test of this point once; I removed both sides of the T/C bushing, leaving just the rod sticking through the hole, then I moved the suspension through the full range of motion. Because I'm using a poly LCA bushing, the LCA was located positively and couldn't twist. I was impressed that the T/C rod remained centered in the mounting hole throughout the whole range of travel. I also realized that any method of locating this rod that alters this point, was going to put a twist in the LCA. A lot of guys use a heim joint bolted into a clevis that stands off of this hole, and others use essentially a ball-and-socket tie rod end, both move the pivot point rearward of the stock pivot point, which isn't ideal, and slightly alters geometry. I like the E.E. kit, because in tension (braking), there will be no deflection, no loss of caster under braking.

If I pursue the pillow bushing above, I'll have to re-build the stock body attachment feature. I may consider raising or lowering the point to alter anti-dive properties as discussed in this important thread...

http://www.the510realm.com/viewtopic.ph ... t=lca+bolt

...but I need to consider all of the ramifications first, I have much to learn.

Hudson, the rubber is quite thin, and is bonded permanetly to teh metal during vulcanization. I doubt this could be recreated. Machining a delrin/nylon sleeve is doable, but this is a high quality off-the-shelf OEM part, which is a big plus to me.