Scotty's 13bpp '71

Re: Scotty's Slackin '71

I would be interested in a set of those tubular arms if they were made available!

Re: Scotty's 13bpp '71

Oh Mighty Mr. Junky, Please don't plant your ass back down again. This project is amazing and I'm dying to see what else you have up your sleeve. Your welding and fab skills are second to none, but your creativity and attention to detail totally floors me. That roll bar is a piece of art man! I can't believe I haven't seen this thread before. Outstanding work, please keep at it Scott.Track Junky wrote:Got off my ass today and finally got around to coating my rear arms and crossmember with POR-15, if you haven't used this stuff before it goes a long way. I have two coats on the arms and xmember and one coat on the diff mustache bar, couple steering knuckles and a few other bits and probably used a 1/4 of a quart of this stuff. A shame to waste the rest of the can. It does say on the can that you can reseal the lid and stick it in the fridge to save it but I completely destroyed the lid trying to get it off! BS man!!

Scott.

Sometimes people loose touch with subjectivity, because they've got they're heads stuck too far up they're own,,, Reality.

Re: Scotty's 13bpp '71

I usually take another can (I get it free from the auto shop) and tape around the top edge of it, pour the POR from it's original can into the second can leaving only the amount of POR that I plan to use in the original can. Close up the second can and toss in the Frig. No POR wasted!RonM wrote:Track Junky wrote:Got off my ass today and finally got around to coating my rear arms and crossmember with POR-15, if you haven't used this stuff before it goes a long way. I have two coats on the arms and xmember and one coat on the diff mustache bar, couple steering knuckles and a few other bits and probably used a 1/4 of a quart of this stuff. A shame to waste the rest of the can. It does say on the can that you can reseal the lid and stick it in the fridge to save it but I completely destroyed the lid trying to get it off! BS man!!

- Track Junky

- Supporter

- Posts: 397

- Joined: 14 Feb 2008 02:18

- Location: Chicago Ill.

Re: Scotty's 13bpp '71

Ha! Cheers Ron!

I'm afraid I'm back on my ass for a while, been saving $'s for a piece of property and finally have a shop for myself to build my junk and possibly make some stuff for 510 guys.

Scott.

I'm afraid I'm back on my ass for a while, been saving $'s for a piece of property and finally have a shop for myself to build my junk and possibly make some stuff for 510 guys.

Scott.

Re: Scotty's 13bpp '71

Nooooo

I'm bummed man! Although a piece of property would be nice, I really think you need to be responsible and get back to work on your car

I'm bummed man! Although a piece of property would be nice, I really think you need to be responsible and get back to work on your car  All kidding aside, I hope it doesn't fall off your radar for too long. I will be checking in from time to time.

All kidding aside, I hope it doesn't fall off your radar for too long. I will be checking in from time to time.

Sometimes people loose touch with subjectivity, because they've got they're heads stuck too far up they're own,,, Reality.

- Datsun 1600 Nut

- Supporter

- Posts: 261

- Joined: 30 Mar 2010 06:51

- Location: Pretoria, South Africa

Re: Scotty's 13bpp '71

Scott,

Those rear arms are just amazing! Great work man! Hopefully one day I will be able to TIG weld like you do...

Hopefully one day I will be able to TIG weld like you do...

Made any progress on the car as of late?

Cheers

Jared

Those rear arms are just amazing! Great work man!

Made any progress on the car as of late?

Cheers

Jared

"When you feel like giving up, remember why you held on for so long in the first place..."

Current Car's:

1971 P510 1600 SSS Coupe

1972 P510 1600 SSS

1972 P510 1600 SSS

1973 P510 1600 SSS

1973 620 Pickup

1979 PA10 1600J

1980 280ZX

Current Car's:

1971 P510 1600 SSS Coupe

1972 P510 1600 SSS

1972 P510 1600 SSS

1973 P510 1600 SSS

1973 620 Pickup

1979 PA10 1600J

1980 280ZX

- Track Junky

- Supporter

- Posts: 397

- Joined: 14 Feb 2008 02:18

- Location: Chicago Ill.

Re: Scotty's 13bpp '71

No new progress but, a close friend of mine is looking to purchase a warehouse in which he is going to rent out some space for me to finally start to finish this project.Datsun 1600 Nut wrote:Scott,

Those rear arms are just amazing! Great work man!Hopefully one day I will be able to TIG weld like you do...

Made any progress on the car as of late?

Cheers

Jared

In the meantime I bought this little Subaru to fulfill my track needs! pic is from a trip to Colorado this Sept, somewhere in the canyons, man this car can carve with the best of 'em.

Scott.

- Datsun 1600 Nut

- Supporter

- Posts: 261

- Joined: 30 Mar 2010 06:51

- Location: Pretoria, South Africa

Re: Scotty's 13bpp '71

Very popular little cars these 86 / BR-Z / FR-S hey? How does she drive?

Just goes to show that RWD is always going to have a special place in true enthusiasts' hearts!

Sounds good on the warehouse space man, looking forward to seeing some more of your sick fabrication skills! Definitely inspiring stuff...

Cheers

Jared

Just goes to show that RWD is always going to have a special place in true enthusiasts' hearts!

Sounds good on the warehouse space man, looking forward to seeing some more of your sick fabrication skills! Definitely inspiring stuff...

Cheers

Jared

"When you feel like giving up, remember why you held on for so long in the first place..."

Current Car's:

1971 P510 1600 SSS Coupe

1972 P510 1600 SSS

1972 P510 1600 SSS

1973 P510 1600 SSS

1973 620 Pickup

1979 PA10 1600J

1980 280ZX

Current Car's:

1971 P510 1600 SSS Coupe

1972 P510 1600 SSS

1972 P510 1600 SSS

1973 P510 1600 SSS

1973 620 Pickup

1979 PA10 1600J

1980 280ZX

-

62 bugzilla

- Posts: 35

- Joined: 10 Nov 2012 22:31

- Location: Plover Wisconsin

Re: Scotty's 13bpp '71

I like the control arm alot and wanted to do some and minitub my car at the same time so I could make the arms to clear a wider inset wheel. I'm not sure yet if I'm going to build them with tubing or make boxed ones with sheet metal? Nice job on yours. Did you use the stock 510 stub axle? I was thinking of using used 930 porshe complete rear arm and use the stub axle, bearing carrier, bearings, rotors and calipers. I had a frreind use these parts on a tube frame ls1 935 porshe.

- Track Junky

- Supporter

- Posts: 397

- Joined: 14 Feb 2008 02:18

- Location: Chicago Ill.

Re: Scotty's 13bpp '71

62 bugzilla wrote:I like the control arm alot and wanted to do some and minitub my car at the same time so I could make the arms to clear a wider inset wheel. I'm not sure yet if I'm going to build them with tubing or make boxed ones with sheet metal? Nice job on yours. Did you use the stock 510 stub axle? I was thinking of using used 930 porshe complete rear arm and use the stub axle, bearing carrier, bearings, rotors and calipers. I had a frreind use these parts on a tube frame ls1 935 porshe.

Sheet metal? Yikes! Not sure how your gonna pull that off but wouldn't mind seeing your ideas.

Yes I used the stock axel assy. Porsche stuff would be cool to use but what about the front? Bolt patterns gonna be different and kinda hard to find a matching set of wheels.

Im very tempted to ditch everything and just start over with a complete tube chassis...maybe!

Scott.

-

62 bugzilla

- Posts: 35

- Joined: 10 Nov 2012 22:31

- Location: Plover Wisconsin

Re: Scotty's 13bpp '71

This is what I meant by sheetmetal rear arms. These are off offroad car but you get the idea.

http://www.competitiveperformancefabric ... G_0577.JPG

http://www.competitiveperformancefabric ... G_0577.JPG

- Track Junky

- Supporter

- Posts: 397

- Joined: 14 Feb 2008 02:18

- Location: Chicago Ill.

Re: Scotty's 13bpp '71

Gotta love the offroad scene. They build some serious rigs! Those arms look great, I say go for it man!

Scott.

Scott.

-

62 bugzilla

- Posts: 35

- Joined: 10 Nov 2012 22:31

- Location: Plover Wisconsin

Re: Scotty's 13bpp '71

They are nice but take about 3 times the work and is best if cad designed and taken to plasma cutter to cut out peices and the tubular you can do by jiging up a stock one and maiking the tubular one on the fly. Sheetmetal has a certain about of bling when done though. I built alot of offroad stuff and the rear arms are a direct crossover peice.

- Track Junky

- Supporter

- Posts: 397

- Joined: 14 Feb 2008 02:18

- Location: Chicago Ill.

Re: Scotty's 13bpp '71

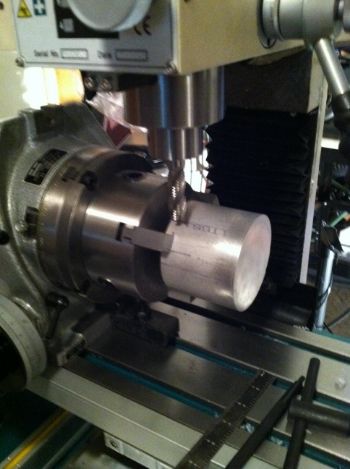

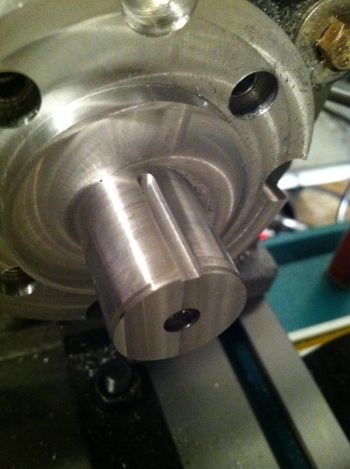

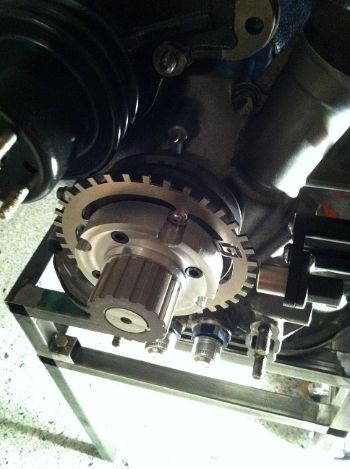

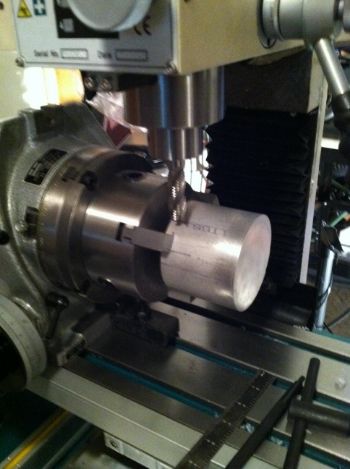

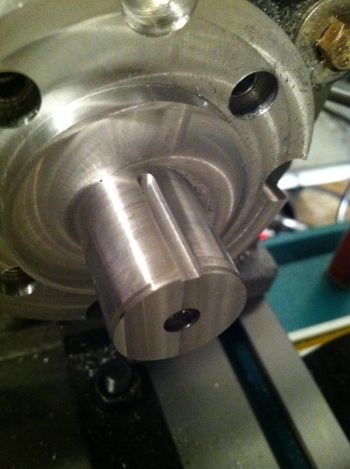

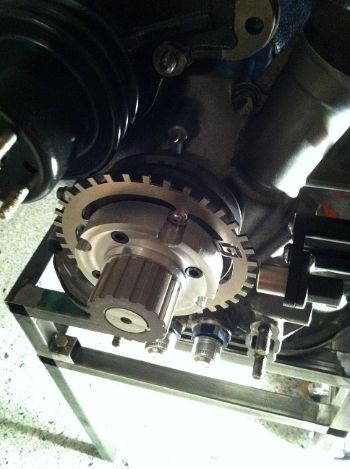

Some small progress on the rotary side of things.

I needed a way to mount this pulley over my crank trigger for my dry sump pump thats gonna be attached to the block, so I figured this would be a good time to break in my new mill I bought a few months back. It's a small manual mill with a decent size table 8'x28"

Added a DRO for the X and Y axis which is just awesome, especially for PCD (bolt pattern stuff) which i used for this job. Keep in mind this is my first milling machine so excuse the excitement!

I also bought a 6" rotary table to do small round cuts if needed which came in very handy. All in all I'm very happy with my little rig!

So I started out with a billet piece of 6061 3.5" round stock which needed to be cut down to 2.5", piece of cake on the band saw.

Loaded up on the rotary table I had to mount it horizontally to cut these slits to hold the work piece in place. I would have left the piece in the 3 jaw chuck but I don't have the stack height on my mill, I'm limited to 13"

On the last picture there will be a bolt and large washer holding back on the pulley so the belt doesn't slip off.

Any way the pics show the process. I'm very happy with the how this little project came out. Any advice or tips and tricks which could have been easier please let me know. I know there are some machinists on this board. Rob and Byron come to mind. Thanks for looking.

Scott.

I needed a way to mount this pulley over my crank trigger for my dry sump pump thats gonna be attached to the block, so I figured this would be a good time to break in my new mill I bought a few months back. It's a small manual mill with a decent size table 8'x28"

Added a DRO for the X and Y axis which is just awesome, especially for PCD (bolt pattern stuff) which i used for this job. Keep in mind this is my first milling machine so excuse the excitement!

I also bought a 6" rotary table to do small round cuts if needed which came in very handy. All in all I'm very happy with my little rig!

So I started out with a billet piece of 6061 3.5" round stock which needed to be cut down to 2.5", piece of cake on the band saw.

Loaded up on the rotary table I had to mount it horizontally to cut these slits to hold the work piece in place. I would have left the piece in the 3 jaw chuck but I don't have the stack height on my mill, I'm limited to 13"

On the last picture there will be a bolt and large washer holding back on the pulley so the belt doesn't slip off.

Any way the pics show the process. I'm very happy with the how this little project came out. Any advice or tips and tricks which could have been easier please let me know. I know there are some machinists on this board. Rob and Byron come to mind. Thanks for looking.

Scott.

Re: Scotty's 13bpp '71

Damn that's cool! very nice! Are you going to have it balanced? or do you think it would even matter??