Jordan's '72 2 door KA project

Re: Jordan's '72 2 door KA project

Killing it...nice tip on the FH bolts too.

Re: Jordan's '72 2 door KA project

WOW, extremely nice work work on the pie cut pipes(well everything really)

Progress is slow, but it is progress non the less.

CV Driveline

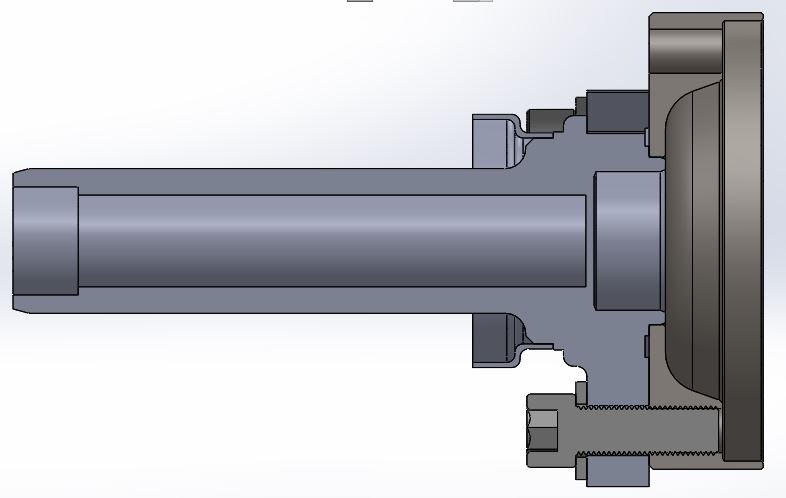

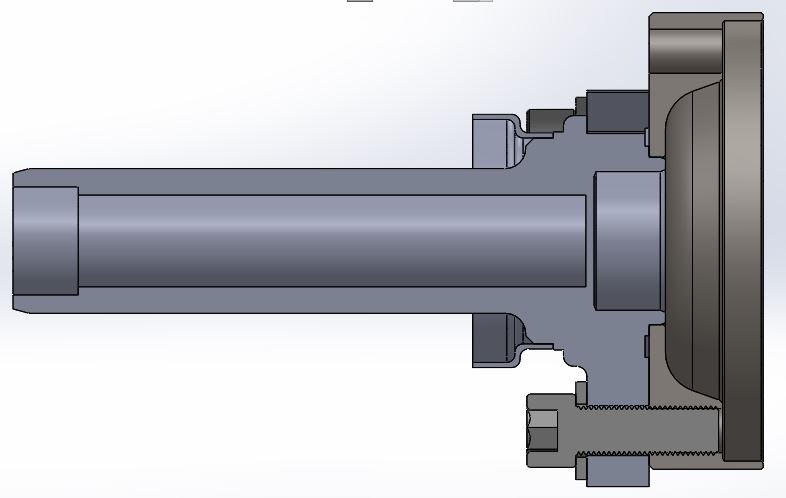

I posted a picture of the raw parts before but I recently made CAD models of them to try to plan what sort of weld interface I could make work.

It's an early (I think) S13 slip yoke with w BNR32 driveshaft CV flange from the halfway point.

Pretty much the largest weld interface I could manage is about 1.75" diameter.

S13 by TRZ Fab, on Flickr

S13 by TRZ Fab, on Flickr

Yoke Xsection by TRZ Fab, on Flickr

Yoke Xsection by TRZ Fab, on Flickr

CV yoke by TRZ Fab, on Flickr

CV yoke by TRZ Fab, on Flickr

With 1/4" conservative weld width, 300HP @4400rpm (optimistic, I know), and 1st gear 3.321, there's only 6,000psi of weld stress so that leaves a good margin for burnout shenanigans etc.

I watched a few YouTube videos on it to get some ideas. Video 1 , Video 2

Their general theme seems to be 4 quick tack welds.

I've pieced together the following idea thus far:

-Machine to suit 3 thou interference fit.

-Assemble with ~1/16" gap and shoulder and hammer pieces true in a lathe

-Preheat to 300F

-Tack weld 4 spots rapidly

-Roboticize the MIG welder and weld out on rotary table

-Air cool and cross fingers

What I'm looking for are some thoughts on how to ensure this beast stays true throughout the welding process.

Anyone done something similar to this before and have feedback?

It's an early (I think) S13 slip yoke with w BNR32 driveshaft CV flange from the halfway point.

Pretty much the largest weld interface I could manage is about 1.75" diameter.

S13 by TRZ Fab, on Flickr

S13 by TRZ Fab, on Flickr Yoke Xsection by TRZ Fab, on Flickr

Yoke Xsection by TRZ Fab, on Flickr CV yoke by TRZ Fab, on Flickr

CV yoke by TRZ Fab, on FlickrWith 1/4" conservative weld width, 300HP @4400rpm (optimistic, I know), and 1st gear 3.321, there's only 6,000psi of weld stress so that leaves a good margin for burnout shenanigans etc.

I watched a few YouTube videos on it to get some ideas. Video 1 , Video 2

Their general theme seems to be 4 quick tack welds.

I've pieced together the following idea thus far:

-Machine to suit 3 thou interference fit.

-Assemble with ~1/16" gap and shoulder and hammer pieces true in a lathe

-Preheat to 300F

-Tack weld 4 spots rapidly

-Roboticize the MIG welder and weld out on rotary table

-Air cool and cross fingers

What I'm looking for are some thoughts on how to ensure this beast stays true throughout the welding process.

Anyone done something similar to this before and have feedback?

'72 2 door KA project | S14 Silvia RB25DET | S14 RB26DETT (sold) | '90 Audi 90Q20V (sold)

Re: Jordan's '72 2 door KA project

Why not just bolt it?

"People don't like it when shit doesn't match their rule of thumb." Sam

- datsuntech

- Posts: 92

- Joined: 27 Apr 2004 16:03

- Location: Winnipeg, Manitoba

Re: Jordan's '72 2 door KA project

I used to work in a driveline shop building driveshafts all day. Industry standard was .007" runout, we used .005" runout as our standard. This made it so that no balancing was necessary although we tacked a small weight on the low side so customers wouldn't complain. Of course this was 4.5" 1/4" wall tubing, but we used the same spec on small stuff too. As far as assembly we put 4 evenly spaced tacks around the tubing on both ends rechecked the runout with a dial indicator and then hand MIG welded each end while hand spinning the shaft on centers. Leave to air cool and they came out dead straight. This is Heavy duty mostly so much more horsepower and torque than your average car. Never had a weld crack or break.

Now I don't know if this is helpful at all, but that's how we did it. Any questions, feel free.

Now I don't know if this is helpful at all, but that's how we did it. Any questions, feel free.

Rear Wheel Drive, The way God Intended.

If a car is being pulled from the front, doesn't that mean it's being towed?

If a car is being pulled from the front, doesn't that mean it's being towed?

- bertvorgon

- Supporter

- Posts: 12021

- Joined: 04 Aug 2003 20:45

- Location: White Rock, B.C. Canada

Re: Jordan's '72 2 door KA project

My first hand experience...Andy made my drive shaft in the lathe, carefully did basically what datsuntech said, and I have NO balance weights and NO issues after 20 years of use.

"Racing makes heroin addiction look like a vague wish for something salty" - Peter Egan

Keith Law

1973 2 Door Slalom/hill climb/road race / canyon carver /Giant Killer 510

1971 Vintage 13' BOLER trailer

Keith Law

1973 2 Door Slalom/hill climb/road race / canyon carver /Giant Killer 510

1971 Vintage 13' BOLER trailer

Re: Jordan's '72 2 door KA project

Thanks for the comments. I really appreciate some real world experience with this stuff. That all makes good sense. I will have a look at the bolted option because it does take a lot of the finesse out of it. Sounds like an over coffee project for tomorrow. I don't have abundant machine shop access so I'm trying to work with what I've got. I'm all ears for a CNC shop that does one or two off stuff too!

'72 2 door KA project | S14 Silvia RB25DET | S14 RB26DETT (sold) | '90 Audi 90Q20V (sold)

Re: Jordan's '72 2 door KA project

More firsthand experience; what you are building is very similar to the way I have built CV stub axles and flanges. Cut down VW bug output flanges to get the CV mounting surface, then machine 510 stub shafts and axle flanges to press-fit the machined VW output flanges. Center everything up in a lathe and tack, check runout and adjust, then finish weld. Just for kicks once the welding is complete I used a rosebud torch to heat the whole assembly up to "red hot" and let it air cool. Built my first set 22 years ago and they are still running strong. Stephen Pepka gave me the recipe back before all the bolt on options became a reality.

Re: Jordan's '72 2 door KA project

Great thanks. I think I found another way to make it work without the welding and all the finesse that goes into that. I should be able to get some parts machined that will allow a simple bolt together assembly with a press fit center to maintain concentricity. For scale, the bolts shown are M12x1.25 Class 12.9 SHCS.

If I go through with this and get these flanges CNCed, is there any interest out there for a CV slip yoke?

Because we are all here for pics:

Bolt Yoke by TRZ Fab, on Flickr

Bolt Yoke by TRZ Fab, on Flickr

Bolt Yoke End by TRZ Fab, on Flickr

Bolt Yoke End by TRZ Fab, on Flickr

Bolt Yoke Xsection by TRZ Fab, on Flickr

Bolt Yoke Xsection by TRZ Fab, on Flickr

The good news is that I'll be able to just shorten my existing driveline to add the front CV joint onto it!

If I go through with this and get these flanges CNCed, is there any interest out there for a CV slip yoke?

Because we are all here for pics:

Bolt Yoke by TRZ Fab, on Flickr

Bolt Yoke by TRZ Fab, on Flickr Bolt Yoke End by TRZ Fab, on Flickr

Bolt Yoke End by TRZ Fab, on Flickr Bolt Yoke Xsection by TRZ Fab, on Flickr

Bolt Yoke Xsection by TRZ Fab, on FlickrThe good news is that I'll be able to just shorten my existing driveline to add the front CV joint onto it!

'72 2 door KA project | S14 Silvia RB25DET | S14 RB26DETT (sold) | '90 Audi 90Q20V (sold)

Re: Jordan's '72 2 door KA project

Cool!

"People don't like it when shit doesn't match their rule of thumb." Sam

Re: Jordan's '72 2 door KA project

Jordan, I think I noticed you had a wanted add on C/L for another 240sx driveshaft? I have one if you are interested. I will put my hands on it on Tuesday if that still works for you?

Re: Jordan's '72 2 door KA project

Yep, guilty lol! Sounds great. Just shoot me a PM if it’s a goofy 3 bolt one and we can go from there. Thanks!

'72 2 door KA project | S14 Silvia RB25DET | S14 RB26DETT (sold) | '90 Audi 90Q20V (sold)

Re: Jordan's '72 2 door KA project

I’ll just leave these pics here for now. Full update later!

- Attachments

-

- 58AE94CE-004F-4A17-9069-9A25BB06999D.jpeg (101.46 KiB) Viewed 4256 times

-

- C41127A1-3FE5-44D7-AB94-58F21FA6A995.jpeg (39.37 KiB) Viewed 4256 times

-

- 4FE53974-2238-48AE-8A44-B0D50F24E5E4.jpeg (93.99 KiB) Viewed 4256 times

-

- 2E42D2A6-26F4-43D1-988F-7BC9FC678657.jpeg (93.94 KiB) Viewed 4256 times

'72 2 door KA project | S14 Silvia RB25DET | S14 RB26DETT (sold) | '90 Audi 90Q20V (sold)

Re: Jordan's '72 2 door KA project

that brakeline? is a work of art.