Page 16 of 17

Re: Lets see some welding and fabrication pics!

Posted: 15 Nov 2015 16:13

by defdes

I just finished making 6 of these glider sofas for that same restaurant down in Miami.

Re: Lets see some welding and fabrication pics!

Posted: 15 Nov 2015 16:34

by Track Junky

Very nice Defdes! You bent all the tubing as well? or automated? either way nice job!

@okayfine you most certainly get what you pay for when it comes to welding gear! Blaze on!

Scott.

Re: Lets see some welding and fabrication pics!

Posted: 15 Nov 2015 18:09

by defdes

All by hand on a Hosfeld. A couple bends were bent straight around a die, but those sweeps are all bump bends every 1". Doing one was hard enough, doing six that match was laborious.

Re: Lets see some welding and fabrication pics!

Posted: 15 Nov 2015 23:00

by Byron510

defdes wrote:All by hand on a Hosfeld. A couple bends were bent straight around a die, but those sweeps are all bump bends every 1". Doing one was hard enough, doing six that match was laborious.

I think someone will be building/buying a roller very soon!

Cool work. I've always wanted to make a spiral stair case in steel, and of course bending that helix handrail would be the key to the whole project.

Bettering that is a double helix spiral stair case with no center post....yeah....

Great work...

Byron

Re: Lets see some welding and fabrication pics!

Posted: 23 Nov 2015 04:46

by defdes

- GEKA.JPG (186.84 KiB) Viewed 5018 times

I do want one of those rollers, but this was first on my list. I haven't got it wired yet but I just bought a rotary phase converter.

55 ton GEKA with a brake station shown right above the punch in the foreground.

Re: Lets see some welding and fabrication pics!

Posted: 23 Nov 2015 06:00

by Byron510

Wow, and iron worker. That's a serious machine for some serious work. Did you manage to swing a pretty good deal on it?

You'll be posting projects at a significantly more efficient rate with that machine, no doubt there.

I'll be in the same position on creating 3ph soon. I'm not sure if I'll get away with a rotors converter though. I searched out the Phase Perfect product, and I think I'll be going that route.

Keep us posted.

Byron.

Re: Lets see some welding and fabrication pics!

Posted: 23 Nov 2015 07:26

by defdes

As this is my only 3 phase machine (7 1/2 hp motor) I got a 20 hp rotary converter which will handle this and another smaller machine if I want to add to the 3 phase collection.

The machine was 8K. more than I wanted to spend, but after doing research, this one with it's guide fences and automatic back stop cutter is the best for precision work....or as close to precision work as I do.

And as you said, the time saved drilling holes, band saw cutting etc, it should pay for itself in a year.

Re: Lets see some welding and fabrication pics!

Posted: 24 Nov 2015 10:02

by Track Junky

Dang! I can use one of those in my shop too!! Very nice!

Scott.

Re: Lets see some welding and fabrication pics!

Posted: 25 Nov 2015 09:14

by Byron510

Scott, I'm still drooling over your fab table you bought....

Re: Lets see some welding and fabrication pics!

Posted: 25 Nov 2015 10:18

by Track Junky

I bought a new lathe too.....need to take a pic...hold on!

Scott.

Re: Lets see some welding and fabrication pics!

Posted: 25 Nov 2015 14:55

by Track Junky

Right, so I bought this a little while back, its an 13x40 which is a good size for me and the work I take on, fun, accurate and repeatable. That tool post is gone, I bought an Aloris quick change post and about a $1k in tool holders and inserts uggghh! Overall a nice addition to my shop.

Scott.

Re: Lets see some welding and fabrication pics!

Posted: 28 Nov 2015 17:00

by Track Junky

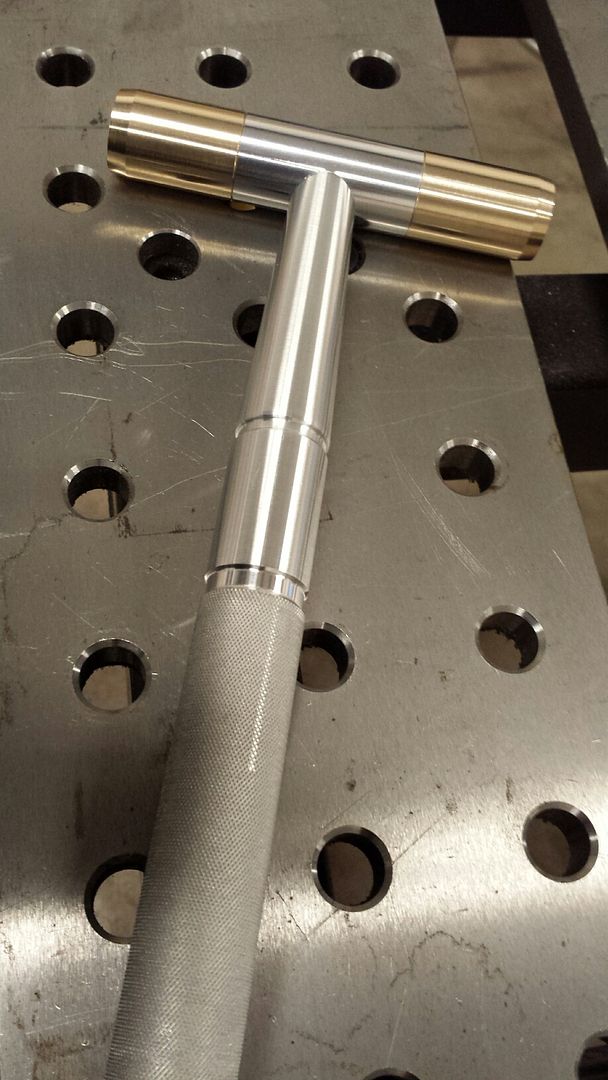

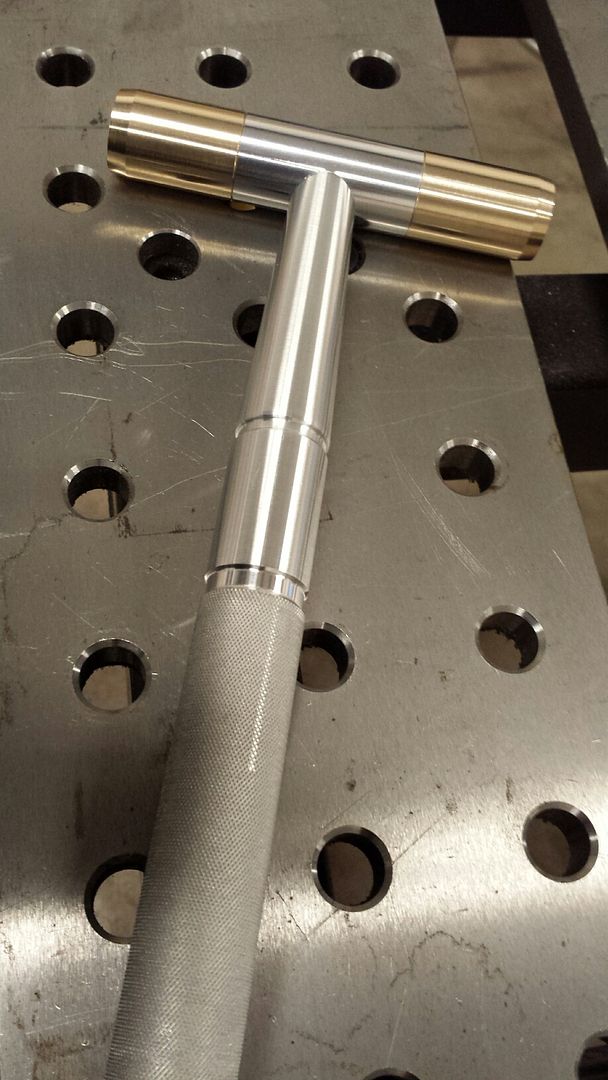

Not welding but, whatever, I assume this is fabrication? lol. Made this little hammer out of 6061 and 932 bearing bronze for the faces. Fun little project on the new lathe, basically just going through all the basic operations, turning, facing, tapers, knurling, threading, etc....overall in length is about 12" on handle and 5" on the hammer double face. 1" o.d. on the handle and faces. Just getting familiar with the new machine and figuring out any odd quirks, overall super happy with it, holding tolerances is a +.

Scott.

Re: Lets see some welding and fabrication pics!

Posted: 30 Nov 2015 11:41

by PoorMtnKid

Wow that is a nice hammer! Were you able to put the eitching in for the handle part?

Re: Lets see some welding and fabrication pics!

Posted: 30 Nov 2015 12:56

by 510rob

PoorMtnKid wrote:Wow that is a nice hammer! Were you able to put the eitching in for the handle part?

Track Junky wrote:...all the basic operations, turning, facing, tapers, knurling, threading, etc...

by etching, did you maybe mean knurling?

Re: Lets see some welding and fabrication pics!

Posted: 01 Dec 2015 08:36

by PoorMtnKid

Sure, if that is what you call the bottom part of the handle. The "grip" area.