510s are scarce in Calgary and the couple I looked at during the last three years were overpriced and full of rust. Actually they didn’t have that much rust, because those areas were completely missing! Last summer I came across one which was 10 minutes from my house, had current Alberta registration and though it was rusted the price was right. I didn’t want a garage queen because my plans were to modify the car and seeing the way prices are increasing there was no way I’d do this to a rust free example. Due to a skipped timing chain I towed the 510 home. Plans were to set it aside until I finished a cab to coupe conversion currently underway on my 911.

I told some friends about my long shot plans for the rusty 510 and they convinced me to do a SR20 turbo swap instead of my planned L20b turbo. I read about the conversion process here on the Realm and got thinking about where to buy a motor and trans which reminded me of a 510 race car I’d seen advertised a year prior. One thing lead to another and I ended up buying the race car for it’s drivetrain and suspension. I guess I was a little absorbed by the project because I acquired both cars in the space of two weeks, no turning back!

In the fall I pulled the drivetrain and running gear from both cars, sold the race car chassis along with all the running gear from the rusted street car then moved everything left over to my work shop space.

So my plans (which evolved L20>SR20) involve a flared chassis, turbo motor, built up suspension and brakes, but remain street-able for Calgary. One friend reminded me of what it was like to drive a 510 in Calgary back in the 80s. Our roads are not any better today, but at the time my 510 had really stiff suspension for the track. Our local track here recently closed and my street driving style is not very aggressive so I’ll be keeping the suspension soft, probably softer than I’d like.

In November I stripped the front end and, no surprise to discover more rust than I anticipated but I’ve got two hands, some tools and a little skill so I got busy. Generally I work on this project during the day between actual work projects but I lack motivation to do much during evenings and weekends. I was off for 12 days during Christmas and new years, never left the city, and I only put in a total of two or three hours on the car. I did however spend 30 or 40 hours lurking on the Realm reading about other peoples projects. I never get tired of seeing other peoples builds and I have no idea where they get the drive to pour on the hours, this is a thing of the past for me.

A few shots of my mess. The street chassis sporting urban assault paint scheme

Race car chassis, sporting the identical paint scheme to the street car, just different colours

Street car tear down

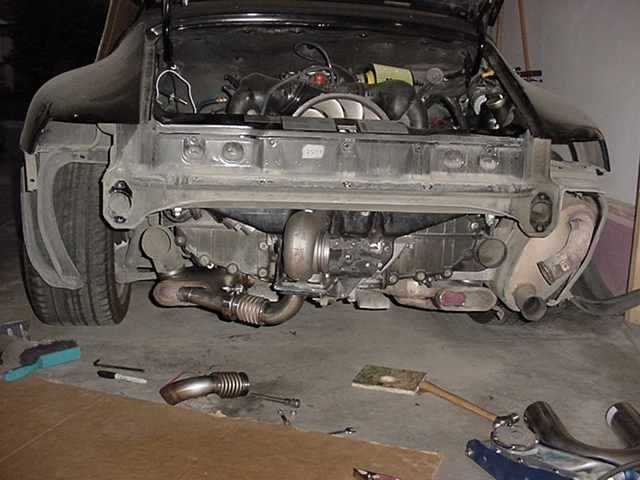

Race car tear down, I sold this chassis along with all the street chassis drivetrain and suspension parts

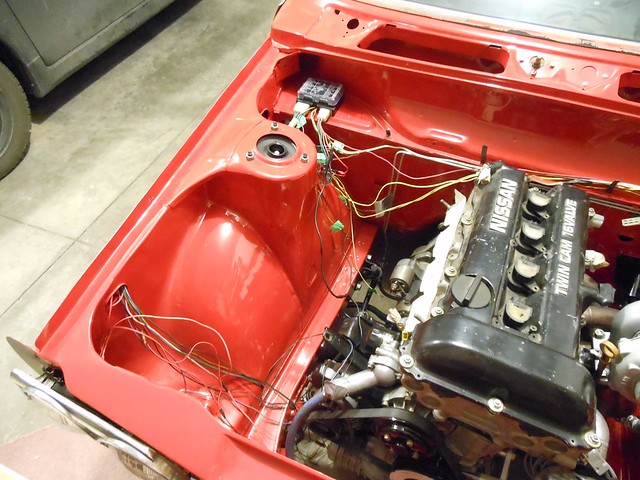

Heart of the race car

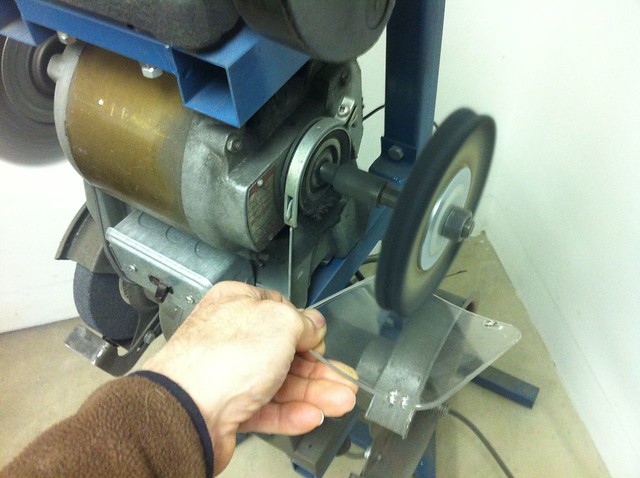

The work on the street car begins. My plan is only to restore the front end of the chassis and the floor pan then proceed with installation of the drive train. Lots of work to replace brake lines, run new fuel plumbing, some wiring etc and bring it up to running. Then, I'll look at moving forward with the rockers, bodywork, flares, paint. Long road ahead, but this won't be a 10/10 restoration, chassis is not worthy.

Usual corrosion to both L and R upper frame rails, fender flanges, bumper mounts, eyebrows.

Drivers floor pan had to be replaced along with the rear 10" of frame rail on both sides. Fun work!

NOT

Post sandblasting, engine bay, bottom of floor pan, inside of floor pan

After detailing a number of spots brought out by sandblasting, then trying to thoroughly blow out the sand (ha) I moved it to a paint shop. I don't really paint but this project will be good practice for me. Being a car guy it's a skill I'm lacking, but then I also know better than to create more work, sometimes it's better to pay someone than create a mess.

Epoxy primed

The race car had a custom Datsport tunnel cover to accommodate the SR20 trans. I welded it in place but did not bother with a continuos weld, just sealed it with seam sealer.

Drivers floor pan inside. The front end has paint (red) but I'm out of time to post up more pictures.

The good thing about getting the car to this stage is seeing some significant progress, colour (of any type) is a sign things are moving along. I have to avoid thinking about how much more work there is. Have the motor running this summer would be nice, and maybe start on the body, but who knows, it might not be complete for a year or two. More pictures tomorrow.