I am using the TSR s15 mount that he supplied with his crossmember. He said the trans sits high up in the tunnel. I will have to definitely do some work on the tunnel when I pull the trans to have room to add more clearance here and there, it only needs it on the passenger side.

Here you can see the mount is pretty tall. I double checked with Mario from TSR and he said it's good.

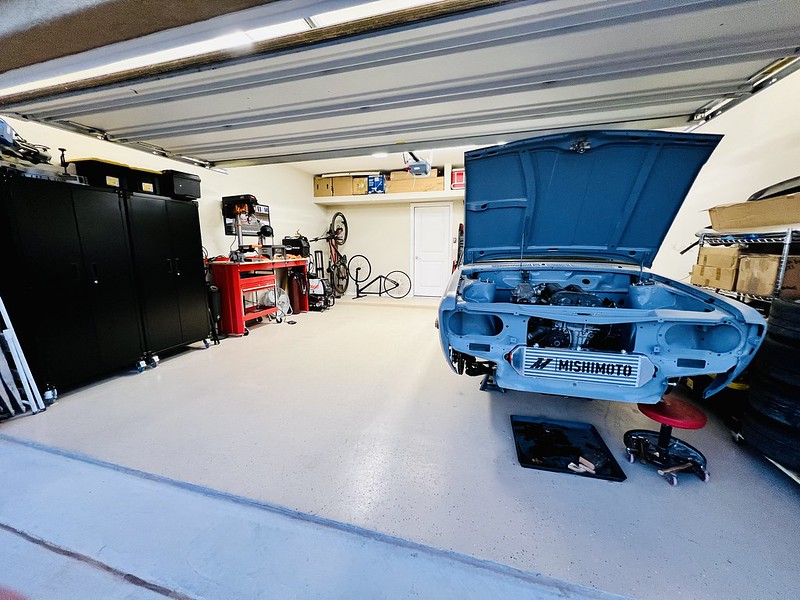

Next I looked at Icehouses IC setup and made some measurements as I will be using the same Rad and IC setup.

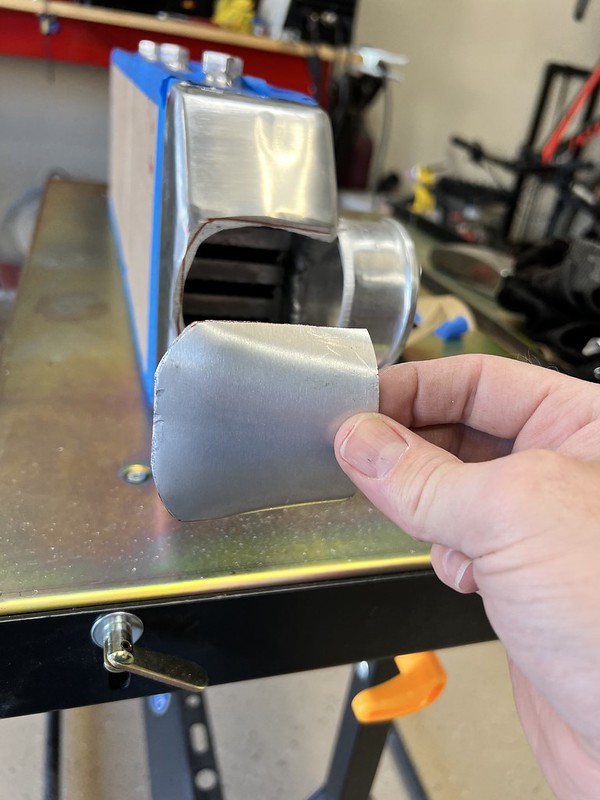

I cut and started to body work a lip into the hole to eventually match the factory one for the radiator.

Here I was checking my work to see where I needed to open up a bit more. I will cut off the inlets and move them to be at 90 degrees with the intercooler, and make patch panels for the stamped holes on each side of the IC. It will look exactly like Icehouses when I am done.

I will be out of town so I will have to wait a few weeks before I can finish working the IC and start to fab a mount for it. While I am here I will install some riv nuts for the front valance for easy of removal. I was also able to find why my bumper was a bit off. When I had it at a shop they welded the front bumper captive nut just a bit off, but its only 1/8 and I also noticed the bumper brackets inside the back of the bumper are a bit off and not perfectly center. I will prob have to slot the brackets a bit to compensate.