Forming Panel Work

Re: Forming Panel Work

Thanks guys. Joel, I do have a shrinker and a stretcher but they are baighleigh copies so I find myself only using them on flanges as they are only good for about an inch deep. The lazze one is nice, but outside of my budget when I bought mine. A Chinese copy of one of these

http://www.machineryhouse.com.au/S226

Byron, you should give it a go on some scrap sheet. You will surprise yourself at how easy the chasing is. This type of panel work (mdf cutout to get a step) is what I will use to make the floor recesses.

http://www.machineryhouse.com.au/S226

Byron, you should give it a go on some scrap sheet. You will surprise yourself at how easy the chasing is. This type of panel work (mdf cutout to get a step) is what I will use to make the floor recesses.

Re: Forming Panel Work

A few questions on shrinking...

1. You heat it up and hammer it. What exactly is happening? Are you thickening the metal around the bend?

2. Should you heat it up to orange and hammer, re heat, hammer, always trying to keep it orange? Or is it more forgiving than that? I'm thinking, like, blacksmithing.

3. I've seen people cut sections out and weld seams together to get curves instead of shrinking the metal. Is there a curve radius or angle factor for deciding between the two methods, or is one better than the other?

4. What's the difference between what you've done (the torch and hammer) and the professional tools you've linked?

1. You heat it up and hammer it. What exactly is happening? Are you thickening the metal around the bend?

2. Should you heat it up to orange and hammer, re heat, hammer, always trying to keep it orange? Or is it more forgiving than that? I'm thinking, like, blacksmithing.

3. I've seen people cut sections out and weld seams together to get curves instead of shrinking the metal. Is there a curve radius or angle factor for deciding between the two methods, or is one better than the other?

4. What's the difference between what you've done (the torch and hammer) and the professional tools you've linked?

Re: Forming Panel Work

Hello Hudson,

1 The metal is thickening where you shrink. What helps me understand the process is to not think about metal like a hard rigid object. Rather think of it like a flowable material. You're flowing excess length into a thicker material.

2 No, try to never take it to orange. All you want is the metal to change to the blue colour. Now, you actually don't need to heat the metal in order to shrink it. I have seen lots of guys shrink with the same process and not require heat. That takes more skill though and more knowledge of how the metal will react. Using heat helps get the metal soft and more compliant to flow. Taking the metal to orange will harden the metal, also try to avoid cooling the metal quickly with water or air as this will harden the metal.

3 I don't believe one is better then the other ( I had to make one cut on the bottom corner of that quarter). If you have an oxy then the cutting and shutting method leaves you with a panel that you can still nicely dress (so I've read/seen demonstrated in videos). With the Mig I find the weld a little too hard to dress further with a hammer. It always surprises me how far you can shrink. What does end up happening though is that the metal gets thicker and therefore becomes harder to work. I don't think there is a limit, but practically, the cutting/shutting method is often quicker for tight radius'.

4 Both shrinking methods take excess material length and shorten it by thickening the material. The tools do this cold (also possible with a hammer and dolly but take time/practice), where as this method uses heat. I also find the tools leave fine marks/wrinkles where you pull the metal together if you are not careful. Personally the tools are just another method, they are not necessary, but I find them helpful for certain things (especially stretching as I'm still working on that). I also think that the manual method gives me more control of how the curve forms.

Finally, if you are having trouble shrinking, start by clamping both ends of your work piece to stop the metal from going back to the original shape. I found this helpful when first starting.

Feel free to ask further questions if I have missed anything.

1 The metal is thickening where you shrink. What helps me understand the process is to not think about metal like a hard rigid object. Rather think of it like a flowable material. You're flowing excess length into a thicker material.

2 No, try to never take it to orange. All you want is the metal to change to the blue colour. Now, you actually don't need to heat the metal in order to shrink it. I have seen lots of guys shrink with the same process and not require heat. That takes more skill though and more knowledge of how the metal will react. Using heat helps get the metal soft and more compliant to flow. Taking the metal to orange will harden the metal, also try to avoid cooling the metal quickly with water or air as this will harden the metal.

3 I don't believe one is better then the other ( I had to make one cut on the bottom corner of that quarter). If you have an oxy then the cutting and shutting method leaves you with a panel that you can still nicely dress (so I've read/seen demonstrated in videos). With the Mig I find the weld a little too hard to dress further with a hammer. It always surprises me how far you can shrink. What does end up happening though is that the metal gets thicker and therefore becomes harder to work. I don't think there is a limit, but practically, the cutting/shutting method is often quicker for tight radius'.

4 Both shrinking methods take excess material length and shorten it by thickening the material. The tools do this cold (also possible with a hammer and dolly but take time/practice), where as this method uses heat. I also find the tools leave fine marks/wrinkles where you pull the metal together if you are not careful. Personally the tools are just another method, they are not necessary, but I find them helpful for certain things (especially stretching as I'm still working on that). I also think that the manual method gives me more control of how the curve forms.

Finally, if you are having trouble shrinking, start by clamping both ends of your work piece to stop the metal from going back to the original shape. I found this helpful when first starting.

Feel free to ask further questions if I have missed anything.

Last edited by Garvice on 18 Mar 2013 15:47, edited 2 times in total.

Re: Forming Panel Work

This is such a great thread. Thanks for sharing your knowledge.

Re: Forming Panel Work

No worries mate, you're welcome.

Re: Forming Panel Work

I'll add this to the cool videos thread too, but you guys have to see this: http://jalopnik.com/watch-the-most-stun ... 1505802218

Re: Forming Panel Work

Cool to see you sharing your techniques and tools. While I'm not an "accomplished panel beater". I've never been afraid to bang on some metal when the opportunity arises.

Nice work on your car

BP

Nice work on your car

BP

1971 Datsun 510 2 door

08 VW R32

69 BSA 650 Firebird Scrambler

Too Many Bicycles

08 VW R32

69 BSA 650 Firebird Scrambler

Too Many Bicycles

Re: Forming Panel Work

Thanks for the video Hudson. Far beyond my skill set though.

No worries BP. I'm not an "accomplished panel beater" either. I just gave it a go (think the attitude/patience is half the battle when doing metal work).

No worries BP. I'm not an "accomplished panel beater" either. I just gave it a go (think the attitude/patience is half the battle when doing metal work).

Re: Forming Panel Work

Here is another great link for sheet metal work.

http://www.garagejournal.com/forum/show ... p?t=182565

http://www.garagejournal.com/forum/show ... p?t=182565

Re: Forming Panel Work

two_68_510s, I guess you were right, finally bought a deep throat shrinker (though a cheaper one than that lazze model).two_68_510s wrote: ↑16 Mar 2013 07:49 Man, if you had a shrinking tool you would be dangerous!!

Very nice hand work, really shows what can be done.

Here is a panel I had to make for a Porsche 911 cabin.

This panel was created from flat sheet with no cutting/welding.

GAS_FAB_P911_054 by Garvice, on Flickr

GAS_FAB_P911_054 by Garvice, on Flickr GAS_FAB_P911_055 by Garvice, on Flickr

GAS_FAB_P911_055 by Garvice, on Flickr GAS_FAB_P911_056 by Garvice, on Flickr

GAS_FAB_P911_056 by Garvice, on Flickr GAS_FAB_P911_057 by Garvice, on Flickr

GAS_FAB_P911_057 by Garvice, on Flickr GAS_FAB_P911_058 by Garvice, on Flickr

GAS_FAB_P911_058 by Garvice, on FlickrFull repair thread can be found here:

https://performanceforums.com/forums/fo ... -cabriolet

- two_68_510s

- Supporter

- Posts: 3894

- Joined: 18 Apr 2010 11:20

- Location: Ben Lomond California

Re: Forming Panel Work

NICE! Talent will tell a story!

Joel

2 '68 510 2 door sedans

'95 240SX

“We will either find a way, or make one.” – Hannibal

2 '68 510 2 door sedans

'95 240SX

“We will either find a way, or make one.” – Hannibal

Re: Forming Panel Work

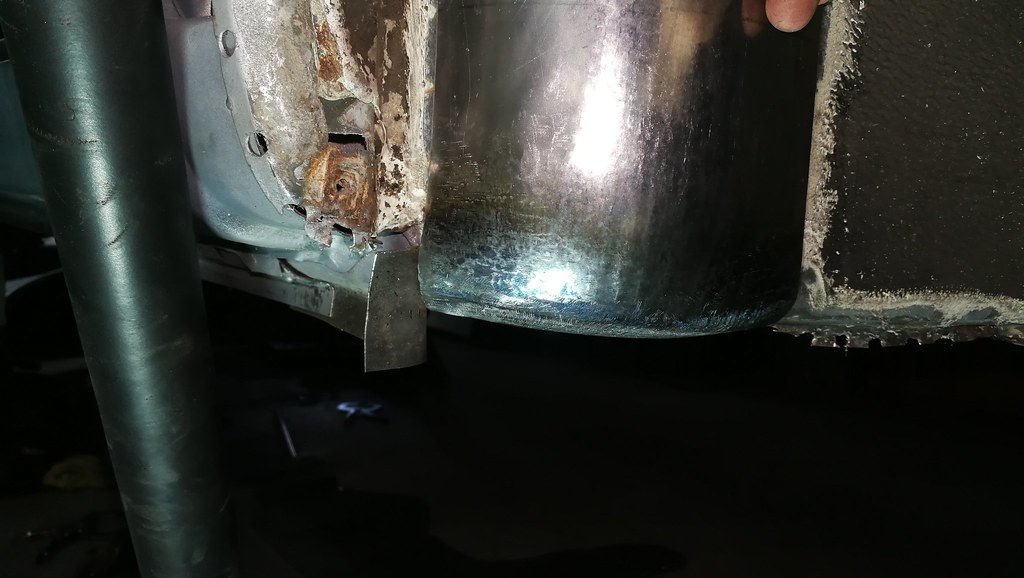

Still haven't had time to get back to my 1600 project, but I have been doing some more customer cars which you guys might be interested in.

Did a mk1 escort

https://performanceforums.com/forums/fo ... mk1-escort

Currently working on an old Falcon

https://performanceforums.com/forums/fo ... ost7223896

Did a mk1 escort

https://performanceforums.com/forums/fo ... mk1-escort

Currently working on an old Falcon

https://performanceforums.com/forums/fo ... ost7223896

Re: Forming Panel Work

I like the slit tube idea. gonna have to make one..for small patches

I havent done much metal hammer forming might take more patience than I have..

I havent done much metal hammer forming might take more patience than I have..

Mike Gibson

Datsun: 71 dime; 73 Z ; GT3 240

Other: 65 + 67 Mustang ; 03 murcie

Datsun: 71 dime; 73 Z ; GT3 240

Other: 65 + 67 Mustang ; 03 murcie

Re: Forming Panel Work

Nice work, but you can see what has recently become available here in the States, & Gerson is talking to someone in Australia to distribute his panels! Check out www.kfvintagejdm.com. Not all of his panels are loaded on the webpage yet, because they are so newly released! He is also on the various Facebook Datsun pages & on Instagram!

1973 510 2dr

1972 521 flat bed

1972 510 Wagon parts car

2009 Toyota Matrix S AWD

LOTS of 510 parts!

1972 521 flat bed

1972 510 Wagon parts car

2009 Toyota Matrix S AWD

LOTS of 510 parts!